Search the internet for “factory automation,” “bar code scanners,” or “RFID,” and discover continuing advances in manufacturing technology. Robots and machines have resulted in quantum leaps in productivity and quality. A similar revolution has occurred in the deployment of job costing technology.

Direct Material

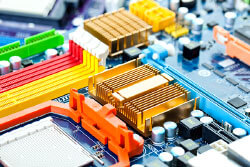

Purchasing a computer requires one to choose components relating to memory, hard drives, and so on. Each unique computer represents a unique job, and will have a unique cost. How can cost data be efficiently captured? If one were to open up the housing on a computer, one would quickly note that many of the expensive parts within have serial numbers, barcodes, or other unique identifiers. These IDs were likely mechanically scanned into a database to match them with the serial number of the finished computer unit. As a result, a computer manufacturer can tell exactly which memory chips, hard drives, etc. are installed on a specific computer. This is helpful for warranty processing, product recalls, and other inventory management issues. But, that same data can also be used to produce a listing of direct material cost for each unit produced.

Purchasing a computer requires one to choose components relating to memory, hard drives, and so on. Each unique computer represents a unique job, and will have a unique cost. How can cost data be efficiently captured? If one were to open up the housing on a computer, one would quickly note that many of the expensive parts within have serial numbers, barcodes, or other unique identifiers. These IDs were likely mechanically scanned into a database to match them with the serial number of the finished computer unit. As a result, a computer manufacturer can tell exactly which memory chips, hard drives, etc. are installed on a specific computer. This is helpful for warranty processing, product recalls, and other inventory management issues. But, that same data can also be used to produce a listing of direct material cost for each unit produced.

Direct Labor

Technology is also used to track and log time to specific jobs via various “login clocks.” Note that the information being tracked is essentially the same as what Donnie was providing to Jack via the daily time sheet, but with added efficiency, accuracy, and control. In addition to monitoring job cost, a manager must also safeguard corporate resources. Here, technology can play a key role.

Newer systems require biometric validation (like fingerprint IDs) of employees working on a project. These tools are used to make sure that employees who claim time working on a job are in fact working on the job. Such systems can also be used to limit access to inventory. Rather than allowing free access to an inventory storage area, or providing a human “guard,” technology can control who comes and goes, and what they take with them when they leave.

Newer systems require biometric validation (like fingerprint IDs) of employees working on a project. These tools are used to make sure that employees who claim time working on a job are in fact working on the job. Such systems can also be used to limit access to inventory. Rather than allowing free access to an inventory storage area, or providing a human “guard,” technology can control who comes and goes, and what they take with them when they leave.

Some products are produced on an assembly line. A designated amount of time is available per task, as the line keeps moving production along at a constant rate. An employee might perform the same operation on 50 or more units per hour. It would take more time to measure and record the labor for each job than it takes to perform the task itself.

In this type of environment, cost is usually assigned to jobs based on the average or standard time for each activity. In essence, if an employee is expected to work on 60 units per hour, one minute of direct labor time/cost would be assigned to each unit for the employee’s specific task. A subsequent chapter will show how deviations from standards are measured and reported.

Overhead And Cost Drivers

The application of overhead to jobs is mostly an exercise in algebra. Jack applied overhead at the rate of $20 for each hour of direct labor. A similar exercise is used to apply overhead in the automated factory environment. Some predetermined scheme is used to apply overhead to production. In a highly mechanized environment, one must give careful thought to the cost driver.

The cost driver is the factor that is viewed as causing costs to be incurred within an organization. It is best viewed only in an abstract context, as there are too many individual variables for any single factor to fully explain all cost incurrence. Labor hours may not be the most significant cost driver in a mechanized setting. Machine hours, number of bar code scans, fuel consumption, or number of assembly steps could each provide a potential basis for allocating overhead. This choice must be logical, as it will govern the allocation of total overhead costs to individual products.

The cost driver is the factor that is viewed as causing costs to be incurred within an organization. It is best viewed only in an abstract context, as there are too many individual variables for any single factor to fully explain all cost incurrence. Labor hours may not be the most significant cost driver in a mechanized setting. Machine hours, number of bar code scans, fuel consumption, or number of assembly steps could each provide a potential basis for allocating overhead. This choice must be logical, as it will govern the allocation of total overhead costs to individual products.

Product pricing, CVP analysis, inventory values, and so forth are dependent upon costing information driven by overhead allocation. This underscores the importance of correct methodology in identifying cost drivers. To do otherwise could result in serious costing errors.

Suppose a computer manufacturer allocated overhead based on the amount of installed memory. As a result, a machine with 2 GB of memory would absorb twice as much overhead as a machine with 1 GB. This is probably not a good idea; there is little difference in the production process needed to manufacture the 2 machines (save and except the difference in direct material cost for memory chips). The faulty overhead allocation could cause management to conclude that the 2 GB machines were too costly to produce, while the 1 GB machines seem a relative bargain.

Management accountants have long studied the overhead allocation problem. With so much at stake, quite a lot of thought has been put into ways to improve this effort. The next chapter will present activity-based costing (ABC). ABC seeks to overcome some of the issues just described by dividing production into its component processes (“activities”) and more closely associating overhead with each unique process. But, ABC has its own limitations, so do not be too quick to dismiss the merits of the overhead allocation approach introduced in this chapter.

| Did you learn? |

|---|

| What are some of the influences of technology on job costing data capture? |

| Define “cost driver.” |

| In a modern manufacturing environment, why might traditional cost drivers produce misleading results? |